- Home

- About Us

- Products

- Packages/Solutions

- Services

- Quality

- Media

- News

- Locations/Contact Us

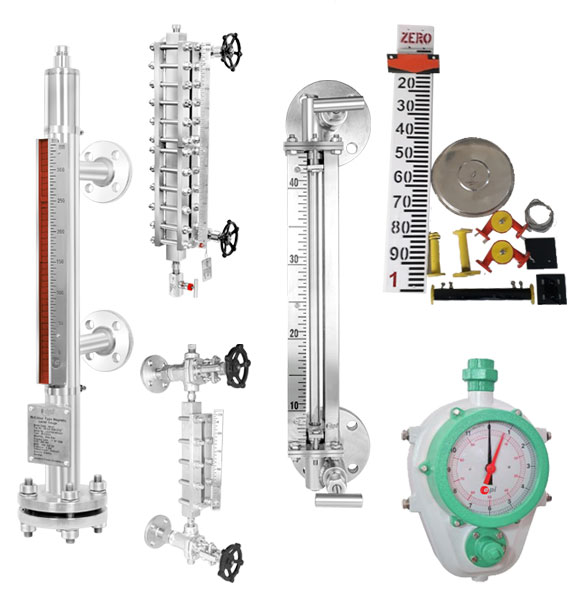

Magnetic Level gauges provides clear, high clarity indication of liquid level. Magnetic float level sensors involve the use of a permanent magnet Sealed inside a float whose rise and fall causes the opening or closing of a mechanical switch, either through direct contact or in proximity of a reed switch.

Reflex glass level gauges working principle is based on the light refraction and reflection laws.Reflex glass level gauges use glasses having the face fitted towards the chamber shaped to have prismatic grooves with section angle of 90°. When in operation, the chamber is filled with liquid in the lower zone and gases or vapors in the upper zone; the liquid level is distinguished by different brightness of the glass in the liquid and in the gas/vapor zone.

Transparent level gauges are fitted with two plate transparent glasses between which the fluid is contained. The fluid level is indicated as the result of the different transparency of the two media and in some cases (for water steam), by conveying upwards on to the surface of separation (between liquid and gaseous substances) a source of light located at the back of the gauge, the rays of which are totally reflected down to the observer.

Tubular Level Gauges are designed to view liquid levels using clear or red line Borosilicate (Pyrex) tubing. All valves use a stuffing box configuration to seal the glass tube, and have a ball check shutoff to prevent loss of vessel contents in case of glass failure. Operating pressure and temperatures are subject to the limitations of the tubular gauge glass and washer composition; consult with pressure products for gauge glass ratings.

Float and Board is a simple economic level measuring instrument for large non pressurized storage tank. Its is a simple float and counter balancing mechanism, float inside the tank and counter weight (scale pointer) connected by the rope wire which is moving freely on the pulley assembly. When the storage tank is empty position, the float located inside the bottom of the scale pointer located at ZERO level on external scale.

Float and tape gauges, also known as “automatic tank gauge. It works by using a large float inside the tank attached to a negator spring via a perforated tape. The negator spring provides constant tension, which balances the float on the liquid. The perforated tape engages pins on a sprocket wheel that, in turn, drives the counter assembly. Alternatively, when a gauge board is used to display level, the negator spring is replaced by a counter weight system.